Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: YZPST-25W1K5F

Brand: YZPST

Supply Type: Original Manufacturer, Odm, Agency

Reference Materials: Photo, Datasheet, Eda/Cad Models

Species: Photoresistor

Craft: Wirewound

Package Type: Surface Mount

Ingredient: Not Applicable

Coating, Shell Type: Not Applicable

Circuit Type: Isolated, Decade Resistor

A +0.5: 18

B +0.5: 19.6

C +0.5: 28

D +0.5: 50

E +0.5: 13.5

F +0.5: 27

G +0.5: 14

Productivity: 10000

Transportation: Ocean,Air

Place of Origin: CHINA

Supply Ability: 100000

Certificate: ISO9001-2008,ROHS

HS Code: 8533100000

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF

Specification of high-power wire winding resistor

POWER WIREWOUND RESISTORS SPECIFICATION

Product type name: RX24

Product Model: 25W 1K5-4K 1%

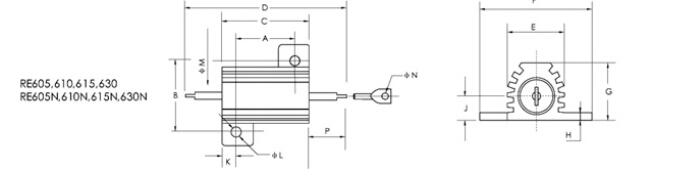

outline dimensional drawing

| TYPE | A +0.5 | B +0.5 | C +0.5 | D +0.5 | E +0.5 | F +0.5 | G +0.5 | H +0.5 | J +0.5 | K +0.5 | L +0.5 | M +0.5 | N +0.5 | P +0.5 |

| 25W | 18 | 19.6 | 28 | 50 | 13.5 | 27 | 14 | 2.0 | 6.4 | 5 | 3.2 | 2.0 | 2 | 10.5 |

1 Scope of application of high power wire around the resistor

2 Model specification RX24-25W 1K5-4K 1%

3 The test state was conducted under normal atmospheric conditions

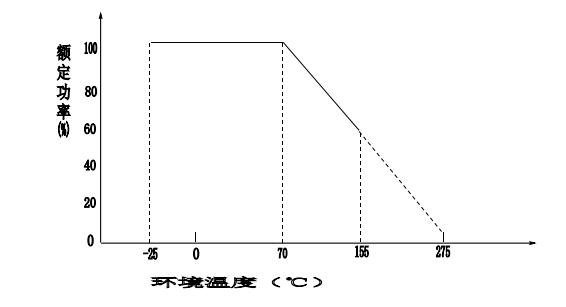

4 Rated power index

4.1 Use temperature range: -25℃ - - + 155℃

4.2 Change in power

The curve of the decreasing rated power with the surrounding temperature.See below

Power reduction curve diagram

4.3 Rated voltage

The rated voltage is determined by the following formula:

![]() E= √ P.R

E= √ P.R

Note: E: Rated voltage (V)

P: Rated power (W)

R: Nominal resistance value of (Ω)

5 Electrical performance

5.1 The Temperature Coefficient

The temperature coefficient does not exceed ± 350PPM /℃

Temperature coefficient = (R-R0)×106/R(t-t0)(PPM /℃)

R0: Stopped at room temperature

R: Test the temperature resistance value

t: room temperature

t0: Test temperature

5.2 Short-term Overload

Pass 5 x rated voltage for 5 seconds, resistance change at ± (2%R + 0.1 Ω).

5.3 Insulation resistance

The resistor is sandwiched in a recess of a 90° metal V-shaped block, measuring voltage current 500V and insulation resistance not less than 500 MΩ.

5.4 Voltage resistance

The resistor is sandwiched in the concave place of a metal V-shaped block, the current current is 500V for 1 minute, and the resistor shall have no obvious breakdown or mechanical damage.

6 Mechanical performance

6.1 Lead end strength

With 20N tensile force, the resistance shape and internal structure are not significantly damaged.

6.2 Resistance

At 10-55HZ and 5mm amplitude uniform vibration for 3 hours, the shape structure has no visible damage.

6.3 Welding heat

Resistance lead immersion (A) 260℃± 5℃, 10s ± 1 second (B) 350℃± 5℃, 3.5s ± 0.5s, immersion depth away from the resistor 3+0.05mm, resistance value changes within ± (1%R + 0.05 Ω) without visible damage.

6.4 Welding

The surface is covered with a smooth and bright solder layer with continuous surface solder without concentrated pinhole, test solder temperature of 235℃± 5℃ and immersion time of 2 ± 0.5 seconds.The surface of resistance lead end is above 95%.

7 Resistant performance

7.1 Durability (Rated load)

At ambient temperature of 70℃, apply rated voltage for 1 hour and 0.5 hours.After 500 hours, there was no visible damage to the resistance appearance, and the resistance value changed within ± (5%R + 0.1 Ω).

7.2 Durability (wet load resistance)

In the relative temperature of 90-95%, the temperature of 40℃ environment, through 1 / 10 rated power voltage for 500 hours, 1 hour through, 0.5 hours off.After 500 hours, the appearance of the resistor has no obvious damage, and the resistance value changed within ± (5%R + 0.1 Ω).

7.3 Rapid temperature change

The resistance is placed in-55℃ environment for half an hour, and then put into 155℃ environment for half an hour. After such 3 cycles, the resistance appearance has no obvious damage, and the resistance value changes within ± (5%R + 0.1 Ω).

7.4 Wet resistance (fixed constant state)

In 40℃ and humidity of 90-95%, meet the DC voltage 100V, resistance terminal to the positive, metal disc connected to the negative, 500 hours, the resistance value changes within ± (5%R + 0.1 Ω).

7.5 Non-combustible characteristics

Use the normal open fire for 15 seconds, stop for 5 seconds, so that after 5 cycles, the resistor does not burst.

8. Contact before the change

Change the materials, manufacturing engineering and management of the product, request the user for quality trust in advance and change before approval.

Product Categories : Electronic Components Resistor > Metal film resistors

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.